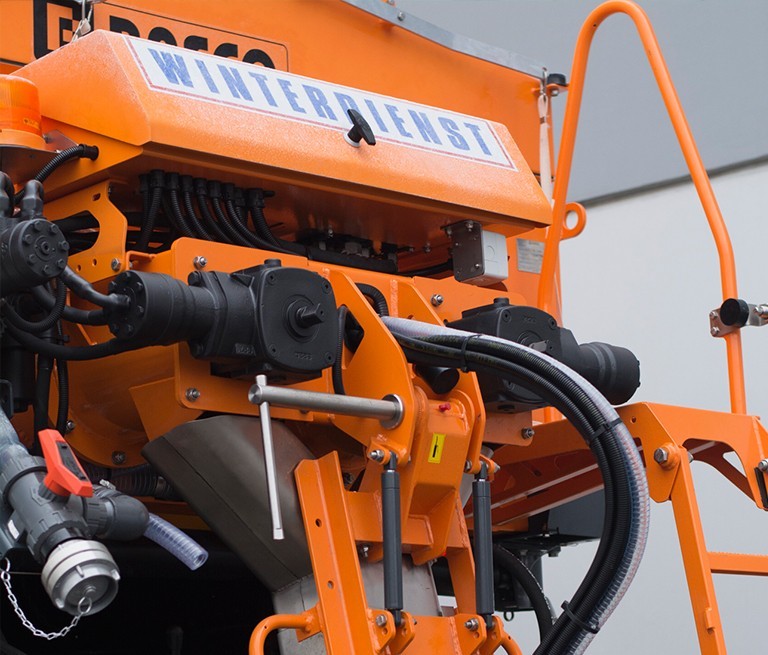

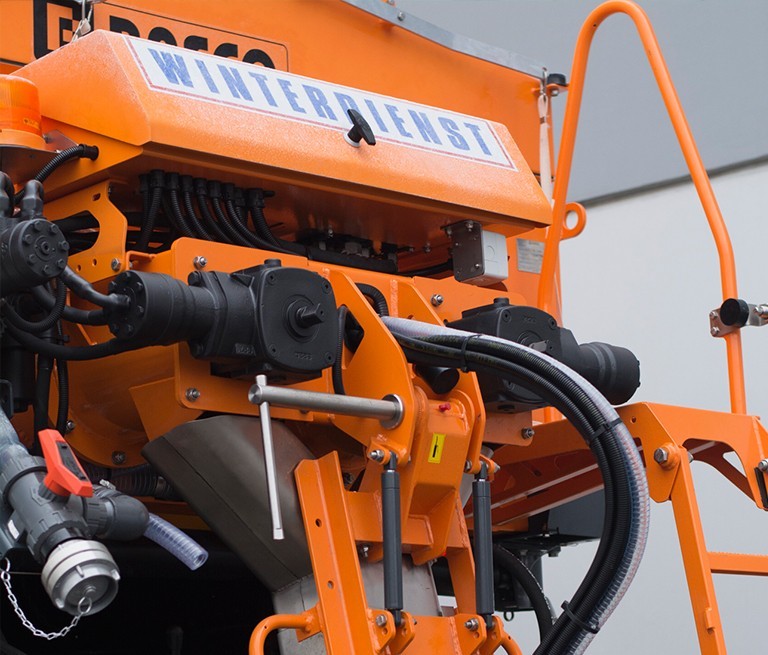

The solid material hopper of the SOLID XF is equipped with two conveyor shafts that allow uniform unloading of the tank with reduced possibility of tunnel effect formation. The XDF distribution version is accompanied by an installed diaphragm that divides the hopper into two chambers in a 2:1 ratio. This allows the spreader to operate simultaneously with two types of solid spreaders.

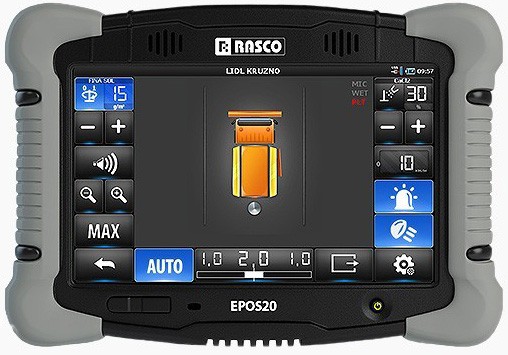

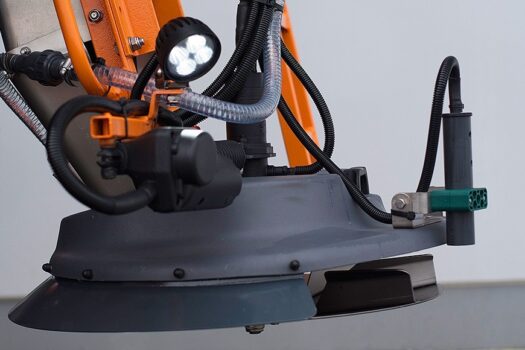

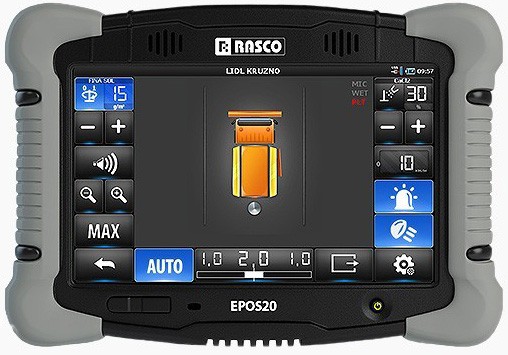

The operation of all RASCO salt spreaders is controlled by the EPOS control modules. Their development by RASCO specialists makes them the leading solution for the control and monitoring of distribution operations. EPOS controls are used to control all parts of the salt spreaders. The control of the spreader hydraulics in combination with the control and feedback system ensures high-precision distribution in all working conditions, while the automated calibration system allows the quick and simple adjustment of the spreader system. The spreader parameters are not lost when the control module is switched off and can be activated automatically the next time the spreader operation starts again.

ARMS is an information and communication system for the control, central monitoring, reporting and optimization of road maintenance activities. Real-time monitoring of working hours of people and machinery as well as resources used (such as salt used, vehicle fuel, etc.) provides the information needed to make immediate and valid decisions to save resources. Unchanged logs protect the user from liability by providing clear information about any action taken, while the reduced consumption of spreading material simultaneously protects the traffic infrastructure and the environment.

It can be done via the vehicle’s hydraulic system or via an independent diesel engine mounted on the spreader frame.