JUNIOR uses an auger conveyor. Auger protection prevents downtime due to an excessive pressure of the spreading material, and an additional cover keeps the spreading material dry, thus reducing the possibility of tunnel effect formation.

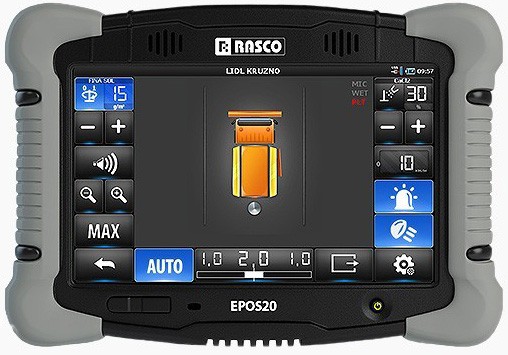

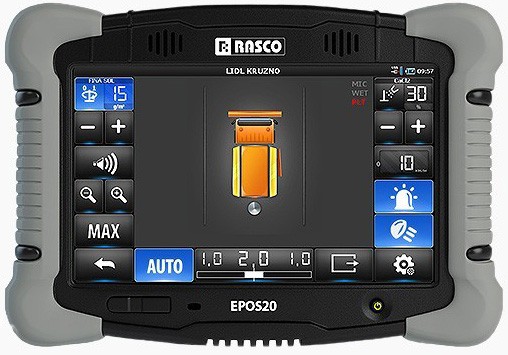

Base version of the JUNIOR spreader is operated as standard with the help of the EPOS 1 control unit. The unit is intended for dry spreading and enables easy monitoring of the spread rate and width. By using the more advanced EPOS 5 control unit, the user gets features such as road-dependent spreading and monitoring of the spreader via the ARMS system.

ARMS is an information and communication system for control, central monitoring, reporting and optimization of activities related to the maintenance of traffic infrastructure. Monitoring of working hours of people and machines as well as of the used resources (such as the used spreading salt, vehicle fuel etc.) in real time creates a unique possibility to quickly decide on potential saving methods. Unchangeable logs protect the user from liability by providing clear information on any taken action, while the reduced consumption of spreading material at the same time protects traffic infrastructure and its surroundings.

Drive via vehicle’s hydraulic system or using one of two available types of hydraulic power unit.